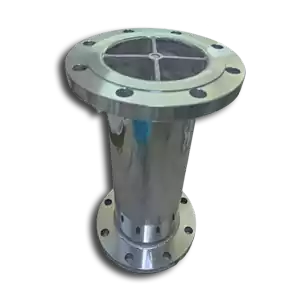

We are Manufacturer, Supplier, Exporter (and also Fabrication Services Provider) of Industrial Static Mixers, Helical Static Mixers, Tab Static Mixers, Inline Static Mixers, Laminar Flow Static Mixers, Wafer Static Mixers, Heat Exchange Static mixers and our setup is situated at Pune, Maharashtra, India.

In the symphony of industrial processes, smooth flow is paramount. But achieving ideal mixing within pipelines can be a complex challenge. At R.K. Engineering, we take the baton and orchestrate perfect harmony with our diverse portfolio of static mixers.

At the core of our success lies our unrivalled design prowess. we excel in tailoring static mixers to meet the unique demands of each application. From laminar flow to turbulent mixing, our designs ensure optimal performance, efficiency, and seamless integration into your processes.

Precision is our forte, and our state-of-the-art manufacturing facility stands as a testament to our commitment to quality. we employ advanced manufacturing techniques and adheres to stringent quality control measures, guaranteeing static mixers that meet the highest industry standards.

We don't offer one-size-fits-all solutions. Our team of skilled engineers collaborates with you to design mixers that perfectly match your specific application and flow requirements.

- Enhanced Mixing Efficiency: Our innovative designs promote thorough blending of fluids, gases, and slurries, optimizing processes and minimizing energy consumption.

- Reduced Shear Stress: Our mixers achieve efficient mixing without excessive shear forces, protecting sensitive materials and preventing product degradation.

- Low Pressure Drop: We prioritize minimal pressure loss across the mixer, maximizing system efficiency and reducing operational costs.

- Durable Construction: Built with high-quality materials like stainless steel, duplex steel, and exotic alloys, our mixers withstand harsh operating conditions and offer long service life.

- Diverse Applications: From chemical processing to water treatment, food and beverage to pharmaceutical industries, our mixers excel in a wide range of applications.

- Blending immiscible fluids and slurries

- Enhancing heat transfer and chemical reactions

- Neutralizing pH and dissolving additives

- Homogenizing liquids and gasses

We offer a comprehensive range of static mixers to meet the diverse needs of various industries, including:

- High-Efficiency Mixers: Designed for maximum mixing performance with minimal pressure drop, ideal for viscous fluids and gas-liquid dispersions.

- Heat Transfer Mixers: Enhance heat transfer processes in reactors and heat exchangers.

- Laminar Flow Mixers: Achieve gentle mixing without shear stress, perfect for shear-sensitive fluids and biological applications.

- Sanitary Mixers: Specifically designed for hygienic applications in the food and beverage and pharmaceutical industries.

All our static mixers are custom sized as per client requirement or application needs.

- MS

- MSRL

- MS-FRP

- SS 304

- SS 316

- SS DUPLEX

- MONEL - 400

- INCONEL - 625

- Flanged end connections

a. Pressure ratings are as per application and client requirement. - Victaulic end connections

- Clamp end connections

- Wafer styled end connections

- Tri clamp end connections

- Union end connections

- Socket and Butt weld end connections

The selection of end connections depends on factors such as the pressure and temperature requirements, the size of the piping system, and the specific need of the application.

- Standard temperature range -20oC to 120oC.

- High temperature range Exceeding 200oC.

- Standard pressure range Up to 290 psi

- High temperature range 455 psi and above

- Helical or twisted elements

- Baffles

- Alternate plates

- Tab or flat blade element

- Intersecting bar or rods

- Paddle elements

- Sigma elements

- Ribbon elements

- Perforated plates or screens

- Vortex generators.

Mixing elements can be removable for easy cleaning and maintenance.

Heating or cooling jackets are provided to static mixers other than heat exchangers. Design depends upon heating & cooling process fluid.

- Chemical processing for blending and reactions.

- Water treatment for chemical dosing.

- Polymerization processes.

- Superior mixing performance

- Laminar flow and high low viscosity mixing

- Liquid dispersion/ gas-liquid contacting

- Cost effective solutions

- Low pressure drops

- Blending of viscous fluids.

- Dispersing gases into liquids.

- Achieving homogeneity in chemical reactions.

- Dispersion of gases in liquids.

- Blending of miscible liquids.

- Emulsification processes.

- Chemical manufacturing.

- Wastewater treatment.

- Food and beverage processing.

- Inline blending of liquids.

- Homogeneous chemical reactions.

- Dilution processes.

- Mixing viscous fluids.

- Blending shear-sensitive materials.

- Improving heat transfer in heat exchangers.

- Gas-liquid dispersion.

- Blending of reactive chemicals.

- Treatment of effluents.

- Water and wastewater treatment.

- Chemical reactions with low-pressure drops.

- Continuous blending in pipelines.

- Biotechnology processes.

- Pharmaceutical manufacturing.

- Shear-sensitive material mixing.

these mixers are designed to facilitate the transfer of thermal energy between different media, ensuring optimal temperature control and process efficiency. The internal section include mixing elements such as helical, tab, vortex or specialized plates that promote turbulence and maximize the contact surface area between the fluids.

- Maintain specific temperature during various stages of drug synthesis, crystallization, and purification in pharmaceutical industry.

- Mixes and help control temperature in cooking, pasteurization, and sterilization processes in food and beverages industry.

- Used in water treatment industry for processes like sludge digestion, where controlled temperatures enhance biological activity.

- Used for process applications, including polymers, plastics, adhesives, hydrocarbon processing, and food industries.

- Effective for both heating and cooling of viscous fluids

- Three-to-ten times greater transfer rates than empty tubes

- Boosts heat transfer with minimal flow disruption

- Custom fabrication to ASME/TEMA standards.

Don't settle for an off-key flow. Let our static mixers harmonise your processes and elevate your operational efficiency. Contact us today and experience the magic of perfect mixing!