We are Manufacturer, Supplier, Exporter (and also Fabrication Services Provider) of Industrial dampers, Louver dampers, Butterfly Dampers, Actuator Dampers, Three Way Dampers, Boiler Draft Dampers, Custom Designed Dampers and our setup is situated at Pune, Maharashtra, India.

In the intricate dance of industrial airflow, dampers are the conductors, orchestrating pressure, velocity, and direction with masterful precision. At R.K. Engineering, we don't just manufacture dampers; we craft them as instruments of control, each one meticulously designed and engineered to meet your specific needs.

A Symphony of Damper Solutions:

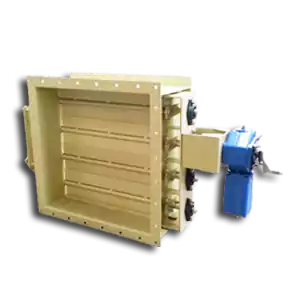

- Butterfly Dampers : The versatile workhorses, ideal for on/off flow control and regulation in diverse applications. Mainly used in duct systems.

- Louver Dampers : Precise airflow modulation with adjustable blades, perfect for ventilation and temperature control.

- Diverter Dampers : Guide airflow in multiple directions, optimizing processes and maximizing efficiency.

- Flue dampers : positioned in chimneys to regulate the draft and control the flow of gases in heating systems.

- High-Pressure Dampers : Engineered to withstand extreme pressures and demanding environments.

- Custom Designed Dampers : We don't shy away from the unique. Our team collaborates with you to create tailor-made solutions for your specific challenges.

Dampers are often exposed to various environmental conditions, including temperature extremes, humidity, and corrosive substances.

Our dampers are typically constructed from corrosion-resistance materials such as galvanized steel, stainless steel, or Mild steel where corrosive substances are absent.

Blade Configuration:

Dampers may feature various blade configurations, including parallel blades, opposed blades, or radial blades. Our blades are designed to minimize air resistance, provide precise modulation, and reduce turbulence for efficient performance.

Frame Construction:

The frame is designed for rigidity and durability, ensuring stability under varying airflow conditions.

Bearings and Bushings:

High-quality bearings or bushings are incorporated to facilitate smooth blade movement and reduce friction.

Sealing Mechanism:

An effective sealing mechanism is crucial to prevent leakage when the damper is in the closed position.

We provide different types of gaskets, seals often made from neoprene or silicone, provide a tight seal. Other than seals our blade overlap design to ensure minimal air leakages.

Manual Operation:

Dampers can be manually operated using hand levers or handwheels for applications where manual adjustment is sufficient.

Motorized/Electric Actuation:

For automated control, motorized or electric actuation systems are employed, enabling precise positioning and remote operation.

Pneumatic/Hydraulic Actuation:

Some applications may require pneumatic or hydraulic actuation for dynamic and responsive airflow control.

We can provide dampers with position indicators, providing visual or sensor-based feedback on the damper's status (open, closed, or partially open).

Pressure Drop:

We design dampers that offers lowest resistance to ventilation or air flow throughout the systems. We ensure that there must be minimum pressure drop when damper is in open position.

Leakage Rate:

Air leakage is minimized through precise blade and seal design, with dampers meeting specified leakage rate standards such as AMCA 500-D.

Size and Configuration:

Dampers are available in various sizes and configurations like blade types, actuation mechanism to accommodate different duct sizes and applications.

Special Coatings:

For specific applications, dampers may have special coatings, such as corrosion-resistant coatings or coatings that comply with industry-specific regulations.

Our damper material and components are selected and designed to withstand the anticipated temperature conditions and ensures longevity and reliability.

Our design gives optimum consideration to ease of maintenance. Our dampers are designed for easy access, inspection, and cleaning to minimize downtime and ensure continued functionality.

- Simple and cost effective.

- Good for on/off control in low-pressure application.

- Not ideal for precise flow control.

- Material

a. Carbon steel: Cost-effective for low-pressure, non-corrosive applications.

b. Stainless steel: More resistant to corrosion and higher temperatures.

- Offer better airflow control than butterfly dampers.

- Good for both on/off and throttling

- Suitable for moderate pressure and temperature

- Material

a. Carbon steel: Cost-effective for low-pressure, non-corrosive applications.

b. Stainless steel: More resistant to corrosion and higher temperatures.

- Multiple blades rotate to control air flow.

- Good for modulating flow in clean air applications.

- Not ideal for tight shutoff or dirty fluids.

- Ideal for high temperature and corrosive substances.

- Flue dampers help prevent the built up of creosote, a flammable residue that can pose a fire hazard.

- Used in boiler, incinerators, and dust collection systems.

- Materials

a. Carbon steel: Cost-effective for low-pressure, non-corrosive applications

b. Stainless steel: More resistant to corrosion and higher temperatures.

c. High-alloy steels: For extreme temperatures and pressures or highly corrosive fluids.

- Airflow control: Dampers regulate the flow of air in ventilation systems, ensuring proper air circulation and temperature control.

- Fresh air intake and exhaust: Dampers control the amount of fresh air entering and stale air exiting a building, maintaining good indoor air quality.

- Fire safety: Fire dampers automatically close in case of a fire, preventing the spread of flames and smoke through ventilation ducts.

- Dust collection systems: Dampers control the flow of dust and fumes in dust collection systems, protecting workers and equipment from harmful airborne particles.

- Fume hoods: Dampers regulate the airflow in fume hoods, capturing hazardous fumes and gases generated during chemical experiments or industrial processes.

- Pipeline control: Dampers control the flow of fluids in pipelines, used in various industrial applications like chemical processing, oil and gas production, and water treatment.

- Boiler flue gas control: Dampers regulate the flow of flue gas from boilers, optimizing combustion efficiency and reducing emissions.

- Turbine air intake: Dampers control the airflow into turbines, ensuring optimal performance and preventing damage from foreign objects.

Don't settle for a discordant airflow. Let our dampers conduct your processes to perfect harmony. Contact us today and experience the power of precision airflow control!

We are not just your average metal fabrication company; we are your trusted partner in bringing your boldest visions to life, one weld, one bend, one intricate cut at a time. Connect with us today and experience the artistry of metal fabrication with R K Engineering. Elevate your projects with precision, passion, and unparalleled craftsmanship.